Which mop uses a preservative to protect noncritical metal items – Preservative-treated mops are essential tools in protecting noncritical metal items from corrosion, a prevalent issue that can compromise their integrity and functionality. This article explores the types of mops that utilize preservatives, their benefits, safety considerations, and best practices for their effective use.

Preservatives play a crucial role in preventing the oxidation of metal surfaces, extending their lifespan and maintaining their aesthetic appeal. By understanding the mechanisms and applications of preservative-treated mops, industries and individuals can effectively combat corrosion and preserve the value of their metal assets.

Mop Types Using Preservatives

Mops treated with preservatives provide an effective means of protecting noncritical metal items from corrosion. These mops utilize various materials and construction methods to ensure optimal performance.

Types of Mops with Preservatives

- Mops with Built-in Preservatives:These mops are manufactured with preservatives incorporated into their fibers. The preservatives are gradually released during use, providing long-lasting protection.

- Mops with Preservative-Treated Heads:These mops have mop heads that are treated with preservatives after production. The treatment process ensures that the mop heads are protected from corrosion.

- Mops with Removable Preservative-Treated Covers:These mops feature removable covers that are treated with preservatives. The covers can be easily replaced when they become worn or damaged.

Benefits of Preservative-Treated Mops

Preservative-treated mops offer several advantages for protecting noncritical metal items:

- Corrosion Prevention:Preservatives inhibit the electrochemical reactions that lead to corrosion, protecting metal surfaces from rust and other forms of degradation.

- Extended Lifespan:By preventing corrosion, preservative-treated mops extend the lifespan of metal items, reducing maintenance and replacement costs.

- Reduced Cleaning Frequency:The protective layer created by preservatives reduces the frequency of cleaning required, saving time and resources.

Preservative Mechanisms and Safety

Preservatives work by forming a protective barrier on metal surfaces, preventing moisture and oxygen from reaching the metal. Common preservatives used in mops include:

- Benzisothiazolinone (BIT):A broad-spectrum preservative effective against bacteria, fungi, and algae.

- Methylisothiazolinone (MIT):A preservative similar to BIT but with a wider range of activity.

- Quaternary Ammonium Compounds (QACs):Cationic surfactants that disrupt microbial cell membranes.

While preservatives are generally safe, some individuals may experience skin irritation or allergic reactions. Proper handling and disposal of preservative-treated mops are essential to minimize risks.

Applications and Best Practices

Preservative-treated mops are ideal for use in various industries and settings where noncritical metal items need protection, such as:

- Manufacturing Facilities:Protecting metal equipment, tools, and machinery from corrosion.

- Healthcare Facilities:Preventing the spread of bacteria and protecting medical equipment from damage.

- Automotive Industry:Preserving metal components and preventing rust.

Best Practices for Using Preservative-Treated Mops:

- Use mops regularly to maintain a protective layer on metal surfaces.

- Rinse mops thoroughly after use to remove any residual preservatives.

- Store mops in a dry and well-ventilated area.

- Dispose of mops according to local regulations.

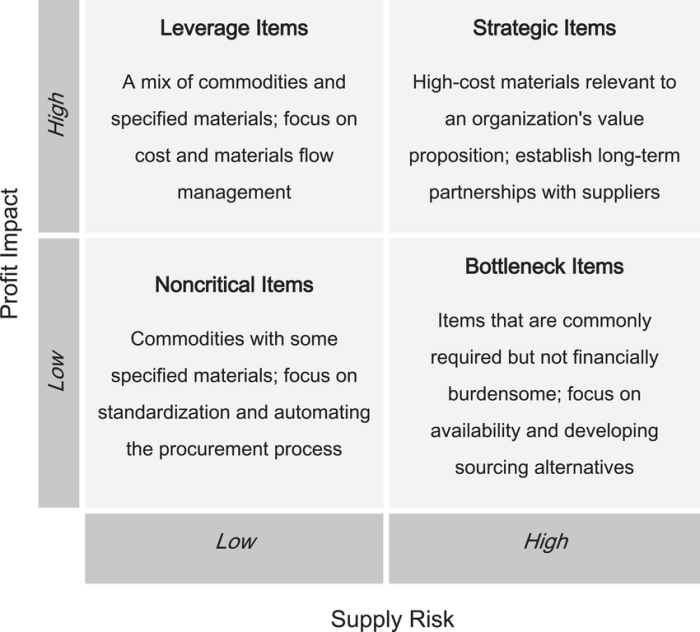

Comparison with Alternative Methods

Preservative-treated mops are one of several methods available for protecting noncritical metal items from corrosion. Other methods include:

- Oiling:Applying a protective oil layer to metal surfaces.

- Coating:Using paints, sealants, or other coatings to create a barrier.

- Vapor Corrosion Inhibitors (VCIs):Releasing volatile chemicals that inhibit corrosion.

The choice of method depends on factors such as the environment, cost, and desired level of protection.

Market Analysis and Trends

The market for preservative-treated mops is expected to grow in the coming years due to increased awareness of corrosion prevention and the need for effective cleaning solutions in various industries.

Emerging trends include:

- Development of eco-friendly preservatives:Reducing the environmental impact of preservative-treated mops.

- Advancements in mop materials:Improving durability and absorbency.

- Increased adoption in healthcare and manufacturing sectors:Growing demand for infection control and equipment protection.

Commonly Asked Questions: Which Mop Uses A Preservative To Protect Noncritical Metal Items

What types of preservatives are commonly used in mops?

Preservatives such as quaternary ammonium compounds, isothiazolones, and organic acids are commonly used in mops to prevent bacterial growth and corrosion.

How often should preservative-treated mops be used?

The frequency of use depends on the specific application and the level of protection required. Regular use is recommended to maintain a protective barrier against corrosion.

Are preservative-treated mops safe for use in food preparation areas?

Mops treated with food-grade preservatives can be used in food preparation areas, provided they are properly rinsed and sanitized before use.