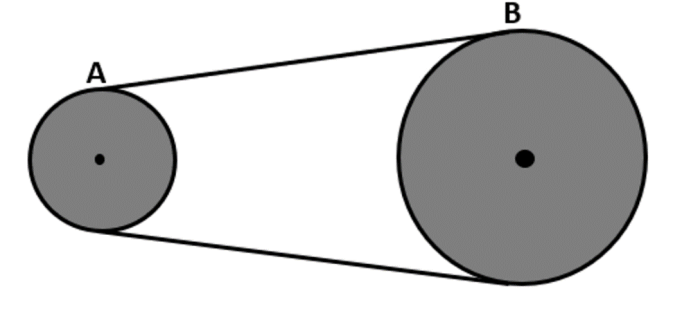

Two pulleys with different radii are attached to a rope, forming a pulley system. This arrangement allows for the lifting of heavy objects with less effort. The radii of the pulleys play a crucial role in determining the mechanical advantage of the system, which is the ratio of the output force to the input force.

In this comprehensive guide, we will delve into the intricacies of pulley systems with different radii, exploring their types, mechanical advantage, efficiency, and applications. By understanding these concepts, engineers and designers can optimize pulley systems for various applications, from construction and manufacturing to everyday tasks.

Introduction

Pulley systems are mechanical devices consisting of grooved wheels and ropes that allow for the transmission of force and motion. They find applications in various fields, including construction, transportation, and manufacturing.

This analysis focuses on pulley systems with different radii, exploring their mechanical advantage, efficiency, and applications.

Pulley Systems with Different Radii: Two Pulleys With Different Radii Are Attached

Types of Pulley Systems

Pulley systems can be classified into two main types:

- Fixed Pulleys:These pulleys are attached to a fixed point and do not move.

- Movable Pulleys:These pulleys are attached to the load and move along with it.

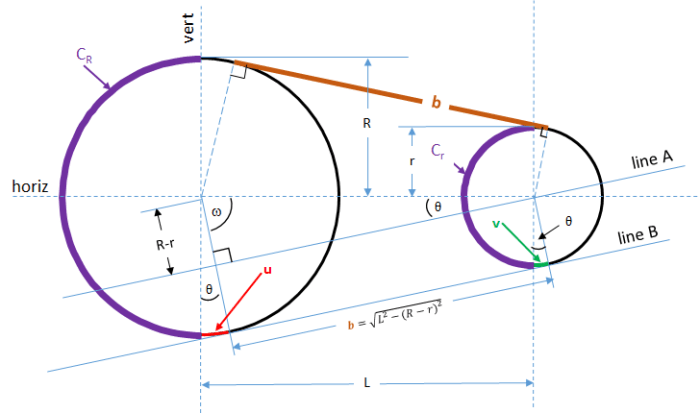

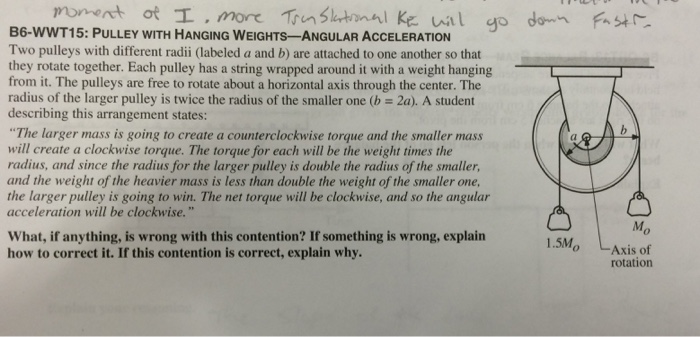

Effect of Radii on Mechanical Advantage

The radii of pulleys play a crucial role in determining the mechanical advantage of a pulley system.

Mechanical advantage is defined as the ratio of the output force to the input force. For a pulley system with different radii, the mechanical advantage is given by:

MA = (r1+ r 2) / r 1

Where:

- MA is the mechanical advantage

- r 1is the radius of the smaller pulley

- r 2is the radius of the larger pulley

This equation demonstrates that the mechanical advantage increases as the radius of the larger pulley increases relative to the radius of the smaller pulley.

Applications

Pulley systems with different radii are used in various applications, including:

- Lifting heavy objects:Cranes and hoists use pulleys with larger radii to lift heavy objects with less effort.

- Changing the direction of force:Pulley systems with different radii can be used to change the direction of force, such as in sailboat rigging.

- Creating speed advantage:Pulley systems with smaller radii on the load side can provide a speed advantage, such as in bicycle gears.

Mechanical Advantage

Definition

Mechanical advantage is a measure of the force amplification provided by a mechanical device.

Calculation, Two pulleys with different radii are attached

The mechanical advantage of a pulley system is calculated as the ratio of the output force to the input force.

Effect of Pulley Radii

As discussed earlier, the radii of pulleys significantly affect the mechanical advantage. Larger radii result in a higher mechanical advantage.

The following table summarizes the mechanical advantage for different pulley systems:

| Pulley System | Mechanical Advantage |

|---|---|

| Single Fixed Pulley | 1 |

| Single Movable Pulley | 2 |

| Compound Pulley (n fixed, m movable) | (2n + 2m) / (2n + m) |

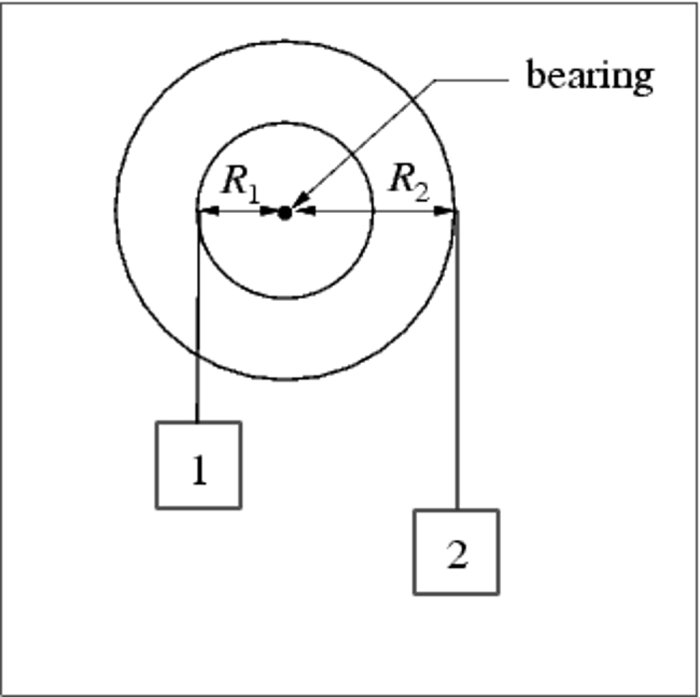

Efficiency and Friction

Factors Affecting Efficiency

The efficiency of a pulley system is influenced by several factors, including:

- Friction:Friction between the rope and the pulley grooves can reduce the efficiency.

- Bearing friction:Friction in the bearings of the pulleys can also contribute to inefficiency.

- Rope stretch:Stretching of the rope under load can reduce the mechanical advantage.

Effect of Friction on Different Radii

Friction has a greater impact on pulleys with smaller radii because the rope wraps around a smaller circumference.

This increased friction reduces the efficiency of the pulley system, resulting in a lower mechanical advantage.

Minimizing Friction

To minimize friction and improve efficiency, consider the following recommendations:

- Use smooth pulleys and ropes:This reduces friction between the surfaces.

- Lubricate the bearings:Regular lubrication reduces friction in the bearings.

- Use high-quality rope:Durable ropes with low stretch minimize efficiency losses.

Applications

Various Applications

Pulley systems with different radii find applications in various industries and situations:

- Construction:Cranes and hoists use pulleys with larger radii to lift heavy materials.

- Transportation:Sailboats use pulleys with different radii to change the direction and magnitude of force applied to the sails.

- Manufacturing:Conveyor belts use pulleys with different radii to control the speed and direction of movement.

Advantages and Disadvantages

Advantages:

- Mechanical advantage: Pulley systems can amplify force, making it easier to lift or move objects.

- Versatility: Different pulley configurations allow for a wide range of applications.

Disadvantages:

- Friction: Friction can reduce efficiency and increase effort.

- Maintenance: Pulleys and ropes require regular maintenance to ensure optimal performance.

Query Resolution

What is the purpose of using pulleys with different radii?

Pulleys with different radii are used to achieve different mechanical advantages. A larger radius pulley will provide a greater mechanical advantage, allowing for the lifting of heavier objects with less effort.

How does friction affect the efficiency of pulley systems?

Friction between the rope and the pulleys can reduce the efficiency of the system. To minimize friction, pulleys should be well-lubricated and the rope should be in good condition.

What are some real-world applications of pulley systems with different radii?

Pulley systems with different radii are used in a wide range of applications, including construction, manufacturing, and everyday tasks. Some examples include lifting heavy objects, hoisting equipment, and changing the direction of a force.